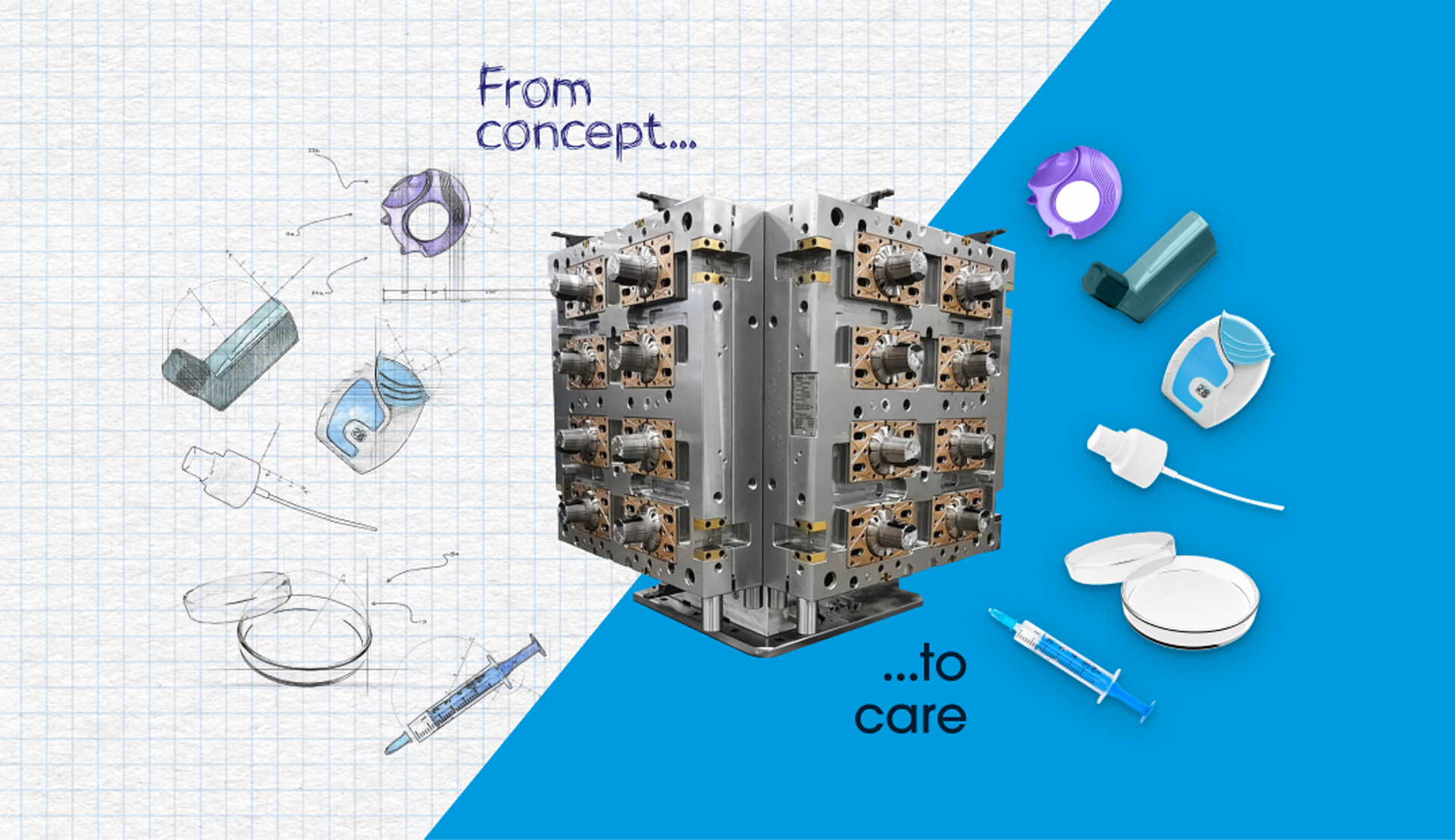

Tooling & molding solutions:

Where innovation

meets precision

Shaping the future of tooling & molding

At Flex, we’re not just about meeting industry standards; we’re about redefining them. Our tooling and molding solutions are designed to give our partners a competitive, enduring edge. But it’s more than that. We’re committed to quality and sustainability, aiming to make a tangible difference in both the market and the world.

PPG differentiation

- Enhanced manufacturability

- Leader in high-cavity precision tooling

- Capability with high-complexity parts

- Extensive experience in parts with tight tolerances

- Vertical integration

- NPI capability

- Creative and innovative solution

- Ability to scale

Get started with Flex

Whether you need flexible business models, advanced product design, world-class manufacturing, supply chain management, or circular economy and sustainability programs, Flex is here to help.

Turning challenges into opportunities

In the tooling and molding industry, challenges are often seen as roadblocks. At Flex, we see them as stepping stones to innovation and efficiency.

Your challenges, our solutions

Diverse solutions tailored to your needs

Every project has its unique challenges and requirements. That’s why we’ve developed a comprehensive range of product types with high-precision capabilities, ensuring that we have the right solution for every need:

Why market-leading brands choose Flex

Choosing a partner like Flex is one of the most important decisions a company can make. We’re more than a partner — we’re a guiding force that will help you navigate every step of your product journey, from design and development to sourcing, manufacturing and logistics.

Crafting the future with responsibility

At Flex, we believe that innovation and responsibility are two sides of the same coin. Our commitment to sustainability is not an afterthought; it’s an integral part of our business model. We understand that to truly make a difference, we must consider the environmental and social impact of our actions at every stage of the product life cycle.

Circular economy pioneers

We’re not just talking about sustainability; we’re living it through our Circular Economy Services. Designed for medical product manufacturers aiming for sustainability, we craft evidence-based strategies that ensure both short- and long-term environmental benefits. Our approach allows resources to flow back into the product lifecycle, offering manufacturers new opportunities for differentiation, cost savings, and innovative business models.

Manufacturing with a conscience

Our commitment to sustainability extends to every aspect of our manufacturing process. From the choice of green, sustainable, and recyclable materials to the implementation of reusable or mono-material packaging, we are dedicated to reducing waste and enhancing recycling rates. Our manufacturing methods are designed to have a positive impact on the product life cycle assessment, influencing how sustainable the disposal or reuse of the device is.

Supply chain excellence

Our supply chain operations are a testament to our commitment to the planet. We leverage our vast component supplier network to manage the procurement of quality parts, mitigating supply chain risks while prioritizing sustainability at every step. Whether it’s tooling & molding or overcoming back order challenges, we ensure a smooth, successful, and sustainable production run.

Our awards & recognitions

Flex’s patient-centered design approach has received multiple industry recognitions including Medical Design Excellence Awards and International Design Excellence Awards for products ranging from a surgical navigation system and a breast biopsy table, to a robotic guidewire delivery system and a pneumatic walking boot.